Top 10 72 In Sanding Belt 3M

We spent many hours on research to finding 72 in sanding belt 3m, reading product features, product specifications for this guide. For those of you who wish to the best 72 in sanding belt 3m, you should not miss this article. 72 in sanding belt 3m coming in a variety of types but also different price range. The following is the top 10 72 in sanding belt 3m by our suggestions

977 reviews analysed

3M Trizact 2 X 72 Inch Sanding Belts A30 (P800), A16 (P1200), A6 (P2500) Grit, 3 Pack Assortment

- 3 Pack Assortment contains 1 each: A30 (P800), A16 (P1200), A6 (P2500) Grit Belts

- 3M Trizact technology delivers consistent, superior results | Number one choice of metalworkers worldwide

- Excellent for sharpening steel knives | Ideal for finishing soft metals (Copper, Aluminum, Brass, etc.) | Also great for fine finishing of hard metals (Stainless Steel, Carbon, etc.)

- Pyramid shaped aluminum oxide abrasive breaks down under pressure, exposing fresh, sharp cutting surfaces as it wears

- Durable, full flex, JE Weight Rayon cloth backing easily conforms to contoured surfaces

Scotch-BriteSurface Conditioning Belt, 72" Length x 2" Width, Medium, Maroon (Pack of 1)

3M Cloth Belt 341D, P180 X-weight, 2 in x 72 in, Film-lok, Single-flex

- Tubeshaped band fits inner and outer contours to remove parting lines, imperfections, and burrs

- Xweight cloth backing withstands heavy sanding and grinding

- Resin bond withstands high heat and pressure

- Tough aluminum oxide abrasive mineral cuts fast and performs well on many substrates

- Bands fit onto a rubber expander wheel attachment (sold separately) for use with a die grinder or rotary drill

Product Description

3M Cloth Belt 341D is a durable aluminum oxide cloth belt recommended for your metal deburring, general metalworking, and some woodworking applications It is suitable for wide belt, edge, or portable belt sanding, and can be used for a variety of applications on metal substrates and wood

From the Manufacturer

The 3M™ Cloth Belt 341D is a durable aluminum oxide cloth belt recommended for metal deburring, general metalworking, and some woodworking applications. It is suitable for wide belt, edge, or portable belt sanding, and can be used for a variety of applications on metal substrates and wood. Fast-cutting aluminum oxide abrasive grains are resin-bonded to a durable X-weight cotton cloth backing to provide continuous cut and long-life performance necessary for more aggressive dry sanding applications. For finishing on metal, the closed coat construction offers a consistent, fine finish, and is suitable for producing a grain pattern. This belt should not be run wet.

Aluminum oxide mineral is a popular choice among industrial professionals because of its cut-rate, durability, and long life. It can be used on a wide variety of materials in both woodworking and metalworking, including ferrous alloys, and is the most commonly used industrial abrasive. The abrasive particles are adhered to the cloth backing with resin, creating a strong bond that withstands high heat and pressure.

Abrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on both wood and metal. 3M offers a broad selection of belts to fit most any industrial belt sander. Wider belts are used with wide belt sanders to dimension or finish wood panels, smooth rough cut edges of metal sheets, or add a grain pattern to stainless steel sheets. Medium-width belts fit onto edge sanders for sanding flat, narrow surfaces such as panel edges; and narrow belts are used with portable belt sanders for sanding or blending wood pieces such as cabinet doors.

Belts come with various splices that join the belt ends. A film media splice achieves a secure bond with a joining film that minimizes chatter marks, ensures a smooth running belt, and produces consistent finishing results. A sine wave splice is constructed of interlocking fingers that enable the splice to travel smoothly over contact wheels, reduce hinging, and provide added strength to the joint area. Sine wave splices are typically used for coarser grades and wide belts.

For more than a century, 3M has applied innovation and technology to improving our customers’ lives and supporting their business goals. Today the company, from its headquarters in St. Paul, Minnesota, serves industrial and commercial customers and consumers in nearly 200 countries. Abrasive Systems products, including a complete line of coated abrasives, microfinishing and microreplicated abrasives, and hardware accessories, provide the finishing touch for almost any surface modification application. The 3M brand, across thousands of products, represents consistency, superior quality, and value.

3M Non-Woven Surface Conditioning Belt – Size: 2" x 72" Grade: A VFN Color: Blue

Product description

3M Scotch-Brite non-woven SC-BS sanding belt uses aluminum oxide as the abrasive material. Since this product is non-woven, grade is generally used to describe the abrasiveness; with the 00579 having a very fine grade. This particular 3M sanding belt is 2 in wide by 72 in long.

From the Manufacturer

The 3M™ Scotch-Brite™ Surface Conditioning Belt in very fine grade is a durable belt engineered to perform detail work such as blending, blending corners, cleaning, contour finishing, deburring, deburring edges, fine finishing, flat finishing, setting the grain, stainless steel finishing, and attaining straightline – brushed finish on a variety of metals. Very fine grade abrasive and high operating speed provides an effective means to achieve professional stainless steel finishes. The non-woven fiber construction runs cool, resists loading, and maintains edge durability while aluminum oxide abrasives provide a high cut-rate for consistent finishing performance over the life of the belt. The 3M™ Scotch-Brite™ Surface Conditioning belt works well to remove coarse grindlines, mill marks, or small burrs left by cutting tools or conventional abrasives. Thin width belts are ideal for blending and finishing right angle welds on stainless steel.

The Scotch-Brite Surface Conditioning Belt uses course grade aluminum oxide abrasive. Aluminum oxide is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

Belt sanders are used for rapid grinding, sanding and finishing on a variety of surfaces. Depending on the material being worked, sanding wheels and discs may clog, quickly making them less efficient, while belt sanders continue to sand without clogging because small grooves in the abrasive belt open as they go around the arc of the drive wheel.

For more than a century, 3M has applied innovation and technology to improving our customers’ lives and supporting their business goals. Today the company, from its headquarters in St. Paul, Minnesota, serves industrial and commercial customers and consumers in nearly 200 countries. Abrasive Systems products, including a complete line of coated abrasives, microfinishing and microreplicated abrasives, and hardware accessories, provide the finishing touch for almost any surface conditioning application. The 3M brand, across thousands of products, represents consistency, superior quality, and value.

3M Trizact Cloth Belt 237AA, 2 in x 72 in A30 X-Weight Full-Flex

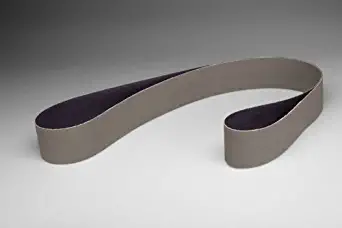

3M Cubitron 777F Coated Ceramic Sanding Belt – 50 Grit – 2 in Width x 72 in Length – 76523 [PRICE is per BELT]

3M 2X72 50YF 777F051144-76523

3M Cubitron II Cloth Belt 984F, 60+ YF-weight, 2 in x 72 in, Film-lok, Single-flex

- 3M Precision-Shaped Grain continuously fractures into sharp points that cut exceptionally fast, helping increase productivity

- Engineered to run cooler, reducing metal discoloration/oxidation and the chance of heat related stress cracks

- Reduces changeouts and downtime in robotic and pressure-assisted applications

- Belt life is significantly longer, producing more parts per belt and requiring fewer belt changes

- YF-weight backing excels in medium/high pressure stainless, cobalt chrome and nickel alloy applications

- 3M Precision Shaped Grain continuously fractures into sharp points that cut exceptionally fast, helping increase productivity

- Engineered to run cooler, reducing metal discoloration/oxidation and the chance of heat related stress cracks

- Precision Shaped Grain requires less pressure, which can mean less operator fatigue

- Belt life is significantly longer, producing more parts per belt and requiring fewer belt changes

- YF-weight backing excels in medium/high pressure stainless, cobalt chrome and nickel alloy applications

Product Description

3M Cubitron II Cloth Belt 984F offers revolutionary performance with 3M Precision-Shaped Grain on a YF-weight polyester cloth backing. This high-performing belt contains a grinding aid, making it ideal for medium to high pressure applications on stainless steel and other exotic alloys, along with carbon steel, cobalt chrome, and nickel alloys.

From the Manufacturer

A revolutionary precision shaped ceramic grain was created that continually fractures into super-sharp points and edges that slice cleanly through metal, rather than gouging or plowing as traditional abrasives do. This creates a super-fast cut and lessens heat build-up in the workpiece, reducing heat-related stress cracks and discoloration. Moreover, because the abrasive itself stays cooler and sharper, it lasts significantly longer than conventional ceramic grain belts, decreasing costs and reducing belt changeovers.

The exceptionally fast cut and long life of ceramic grain make this belt ideal for industrial environments. It is also heat resistant, produces a uniform finish over the life of the product, and helps eliminate burning during end-grain sanding applications. The YF-weight cloth backing on the 984F belt provides durability and the mineral is resin bonded to the backing for reliable performance, even under high heat and pressure.

Proprietary 3M Cubitron II products have raised the bar for high-performing abrasives. Engineers started with 3M Ceramic Abrasive Grain and used technology to electrostatically orient each triangular structure on the backing to form sharp peaks and maximize cutting potential. These peaks act like individual cutting tools that slice through metal, and continuously shelf-sharpen as the points break off, ensuring extended high performance in heavy-duty production applications. The grains wear evenly and provide extra-long life and consistency with less grinding pressure. The result is that Cubitron II products outcut and outlast every conventional ceramic industrial abrasive product on the market, maximizing productivity and minimizing belt stress and operator fatigue.

Abrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on metal substrates. 3M offers a broad selection of belts to fit most any industrial belt sander. Wider belts are used with wide belt sanders to dimension metal sheets, coils or add a grain pattern to stainless steel. Medium-width belts are used on backstands to remove welds, material removal and to set the grain in stainless steel. Narrow belts are used with portable belt sanders for grinding or blending right angle fillet welds.

Belts come with various splices that join the belt ends. 3M Cubitron II Cloth Belt 984F has a fabric splice for added strength when grinding in medium to high pressure applications.

3M Cloth Belt 341D, P400 X-weight, 2 in x 72 in, Film-lok, Single-flex

Scotch-Brite Surface Conditioning Belt, 2 in x 72 in, A MED, 10 per case

- Nonwoven, surface conditioning belts clean, blend, deburr and finish

- Reduced loading and heat build-up allow extended operating time and consistent surface conditioning results

- Conformability allows abrasive to stay in contact with complex-shaped parts in robotic processing

- Reinforced backing and nonwoven open web material provide superior flexibility for detail work, over contours and edges

- Removes surface imperfections, grind lines, mill, and other marks

Product Description

Scotch-Brite Surface Conditioning Belt is a durable belt engineered to perform detail work such as blending, blending corners, cleaning, contour finishing, deburring, deburring edges, fine finishing, flat finishing, setting the grain, stainless steel finishing, and attaining straightline-brushed finishes on a variety of metals.

From the Manufacturer

The 3M™ Scotch-Brite™ Surface Conditioning Belt in medium grade is a durable belt engineered to perform detail work such as finishing, cleaning, finishing, blending, and light deburring on a variety of metals. Medium grade abrasive and high operating speed provides an effective means to achieve #4 stainless steel finishes. The non-woven fiber construction runs cool, resists loading, and maintains edge durability while aluminum oxide abrasives provide a high cut-rate for consistent finishing performance over the life of the belt. The 3M™ Scotch-Brite™ Surface Conditioning belt works well to remove coarse grindlines, mill marks, or small burrs left by cutting tools or conventional abrasives. Thin width belts are ideal for blending and finishing right angle welds on stainless steel

The Scotch-Brite Surface Conditioning Belt uses course grade aluminum oxide abrasive. Aluminum oxide is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

Belt sanders are used for rapid grinding, sanding and finishing on a variety of surfaces. Depending on the material being worked, sanding wheels and discs may clog, quickly making them less efficient, while belt sanders continue to sand without clogging because small grooves in the abrasive belt open as they go around the arc of the drive wheel.

For more than a century, 3M has applied innovation and technology to improving our customers’ lives and supporting their business goals. Today the company, from its headquarters in St. Paul, Minnesota, serves industrial and commercial customers and consumers in nearly 200 countries. Abrasive Systems products, including a complete line of coated abrasives, microfinishing and microreplicated abrasives, and hardware accessories, provide the finishing touch for almost any surface conditioning application. The 3M brand, across thousands of products, represents consistency, superior quality, and value.

3M 27733 Cloth Belt 977F, 3/4" x 72" 50 YF-Weight

Conclusion

By our suggestions above, we hope that you can found 72 In Sanding Belt 3M for you.Please don’t forget to share your experience by comment in this post. Thank you!

Our Promise to Readers

We keep receiving tons of questions of readers who are going to buy 72 In Sanding Belt 3M, eg:

- What are Top 10 72 In Sanding Belt 3M for 2020, for 2019, for 2018 or even 2017 (old models)?

- What is Top 10 72 In Sanding Belt 3M to buy?

- What are Top Rated 72 In Sanding Belt 3M to buy on the market?

- or even What is Top 10 affordable (best budget, best cheap or even best expensive!!!) 72 In Sanding Belt 3M?…

- All of these above questions make you crazy whenever coming up with them. We know your feelings because we used to be in this weird situation when searching for 72 In Sanding Belt 3M.

- Before deciding to buy any 72 In Sanding Belt 3M, make sure you research and read carefully the buying guide somewhere else from trusted sources. We will not repeat it here to save your time.

- You will know how you should choose 72 In Sanding Belt 3M and What you should consider when buying the 72 In Sanding Belt 3M and Where to Buy or Purchase the 72 In Sanding Belt 3M. Just consider our rankings above as a suggestion. The final choice is yours.

- That’s why we use Big Data and AI to solve the issue. We use our own invented, special algorithms to generate lists of Top 10 brands and give them our own Scores to rank them from 1st to 10th.

- You could see the top 10 72 In Sanding Belt 3M of 2020 above. The lists of best products are updated regularly, so you can be sure that the information provided is up-to-date.

- You may read more about us to know what we have achieved so far. Don’t hesitate to contact us if something’s wrong or mislead information about 72 In Sanding Belt 3M.

![3M Cubitron 777F Coated Ceramic Sanding Belt - 50 Grit - 2 in Width x 72 in Length - 76523 [PRICE is per BELT]](https://images-na.ssl-images-amazon.com/images/I/617-jb9qYbL._SL1500_.jpg)